Introduction to Swivel Casters

Swivel casters are fundamental components in many everyday products and industrial equipment, playing a vital role in enhancing mobility and reducing user strain. Designed to rotate a full 360 degrees, swivel casters enable smooth and effortless movement in any direction, making them invaluable for environments where equipment and furniture need to be both mobile and easily maneuvered.

From hospital corridors to busy manufacturing floors, the efficiency that comes with quality casters can make a significant difference in safety and workflow. Whether moving a heavy warehouse cart around tight corners or simply repositioning an office chair, choosing the right caster directly impacts efficiency and floor protection.

These simple yet indispensable devices come in a wide range of types and materials to suit varying needs. Understanding the distinctions in caster construction and function helps users select products that not only improve movement but also promote ergonomic practices and reduce the risk of workplace injuries.

Thanks to innovations in caster design and materials, selecting the proper caster involves more than just weight capacity. Factors such as environment, surface type, and potential exposure to chemicals or moisture must be considered for optimal performance and safety.

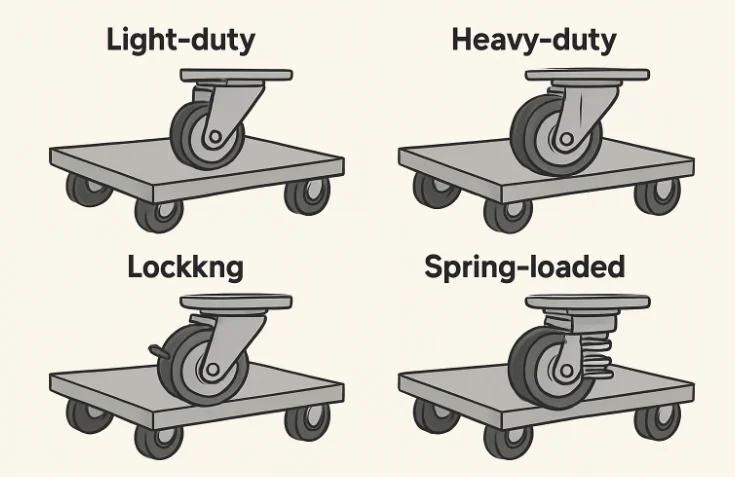

Common Types of Swivel Casters

- Light-Duty Swivel Casters: Suitable for applications involving lower loads, such as office chairs, supply carts, and various household furniture. These casters often use rubber or synthetic wheels that glide quietly over hard indoor floors.

- Heavy-Duty Swivel Casters: Engineered for demanding industrial use, these casters can easily support the immense weight of large machinery, shipping pallets, and manufacturing carts. Durable materials like steel and cast iron ensure longevity and stability under harsh use.

- Locking Swivel Casters: With integrated braking systems, locking casters are vital for safety. They keep equipment stationary when needed, preventing unwanted movement in dynamic environments such as hospitals or laboratories.

- Spring-Loaded Swivel Casters: These specialty casters absorb shocks and dampen vibrations, making them ideal for delicate instrumentation or electronic equipment that must be protected during transit over bumpy or uneven surfaces.

Materials Used in Swivel Casters

The composition of a swivel caster directly influences its performance and its ability to withstand environmental challenges. Choosing the right wheel or housing material is critical when considering long-term durability, safety, and the floors your equipment will move across. According to Wood Magazine, understanding the properties of different wheel materials can help ensure optimal performance for your application:

- Rubber: Provides quiet operation and effective shock absorption, perfect for reducing noise and protecting floors in indoor settings. Soft rubber is especially beneficial for sensitive surfaces.

- Polyurethane: Renowned for its chemical resistance and superior floor protection, polyurethane wheels are often used in hospitals, food processing facilities, and other settings that demand cleanliness and resilience.

- Steel and Cast Iron: These extremely tough materials are chosen for environments where heavy-duty performance is essential. They offer unmatched strength and wear resistance but may require floor protection if used on delicate surfaces.

- Nylon and Polypropylene: Offering a lightweight and corrosion-resistant solution, these materials excel where exposure to moisture, oils, or chemicals could damage other wheel types. Their sleek surface also helps resist debris build-up.

Applications of Swivel Casters

It’s difficult to overstate the versatility of swivel casters. Their applications span nearly every sector, adapting to meet a variety of mobility challenges:

- Healthcare: Quiet, non-marking casters on hospital beds and medical equipment enhance patient comfort and streamline care delivery. Smooth mobility is critical in fast-paced clinical environments.

- Manufacturing: Carts used for heavy assemblies, machinery, or raw materials rely on heavy-duty casters to ensure safe and efficient movement, thereby enhancing production flow in large facilities. This highlights how casters boost safety and efficiency in industrial work environments.

- Retail: Swivel casters enable shopping carts, display units, and stocking trolleys to be easily positioned or shifted, offering both customers and employees enhanced access and convenience.

- Hospitality: In hotels and restaurants, trolleys and service carts equipped with quality casters ensure smooth, quiet delivery of food and beverages—a key factor in maintaining high service standards.

Choosing the Right Swivel Caster

Making the right selection is crucial for both efficiency and safety. Several key elements must be considered to match a caster to a specific need:

- Load Capacity: Assess the total weight the caster must bear, including any dynamic loads from movement or impacts.

- Floor Type: Use caster wheels compatible with your flooring to prevent scuffs, dents, or damage and maximize user safety.

- Environmental Conditions: Consider conditions such as excessive moisture, temperature extremes, or potential exposure to corrosive chemicals when selecting wheel materials.

- Maneuverability Requirements: Evaluate whether advanced features like 360-degree rotation, brakes, or shock absorption will be necessary for your chosen application.

Maintenance and Safety Tips

Maintaining swivel casters is vital to prolonging their lifespan and avoiding workplace injuries. Here are a few best practices:

- Inspection: Routinely examine casters for wear, such as flat spots, cracked wheels, or loose mounts.

- Lubrication: Regularly grease bearings and swivels to ensure smooth, quiet operation and prevent seizing.

- Cleaning: Remove accumulated debris from around the wheel and axle to prevent blockages or inefficient rolling. For a step-by-step guide on thoroughly cleaning rolling chair wheels, see this Wikihow article.

- Replacement: Address any damaged or excessively worn casters immediately to avoid accidents or further equipment damage, as recommended by industry safety guidelines.

Conclusion

Swivel casters are crucial for improving mobility, safety, and efficiency across a wide range of industries. By understanding the types, material selections, and application requirements, users can choose the best casters to fit their needs and maintain optimal workplace conditions. Regular maintenance ensures safety and durability, helping get the most out of an essential mobility solution.

/home/u448362301/domains/theexpotab.com/public_html/wp-content/themes/foxiz/templates/popup.php on line 167

/home/u448362301/domains/theexpotab.com/public_html/wp-content/themes/foxiz/templates/popup.php on line 167