In the ever-evolving textile industry, ensuring the comfort and functionality of fabrics is paramount. One of the most critical aspects of textile quality control is the assessment of fabric performance, specifically when it comes to the sensation of coolness that a fabric can provide. This cool feeling has become an essential feature for many garments, particularly those designed for active wear, sports apparel, and outdoor clothing. As such, Cool Feeling Testing has become an integral part of textile quality assurance, helping manufacturers deliver products that meet consumer expectations for comfort and performance. In this article, we explore the significance of Cool Feeling Testing, the instruments used in the process, and how standardizing these tests helps improve textile quality control.

The Importance of Cool Feeling in Textiles

The demand for textiles that offer a cooling effect has surged in recent years. As more consumers prioritize comfort and performance, especially in hot climates or during physical activity, fabrics that provide a cooling sensation seeking are increasingly sought after. The cool feeling sensation is generally associated with fabrics that wick moisture away from the skin, promote air circulation, and absorb heat from the body. However, determining how well a fabric delivers this effect requires standardized testing to ensure consistency and accuracy.

Cool Feeling Testing measures the ability of a fabric to produce a cooling sensation when it comes into contact with the skin. The results of these tests help determine whether a fabric is suitable for its intended use, especially in applications where comfort during physical activity or exposure to heat is crucial. Without reliable testing standards, manufacturers would struggle to guarantee the performance of their products, potentially leading to consumer dissatisfaction and damage to brand reputation.

The Role of Cool Feeling Machines in Testing

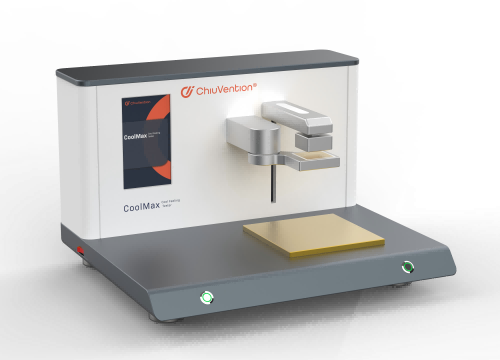

To accurately measure the cool feeling effect of fabrics, testing machines are required. A Cool Feeling Machine is a specialized instrument designed to simulate the interaction between fabric and skin. These machines often use sensors to measure the fabric’s thermal conductivity, moisture-wicking ability, and heat absorption properties. By replicating real-world conditions, a Cool Feeling Machine provides objective, reproducible results that can be used to compare different fabrics and ensure that they meet the desired standards.

A Cool Feeling Machine typically measures the fabric’s ability to lower skin temperature or to provide a pleasant sensation of cooling. The machine simulates the heat exchange between the fabric and the skin through precise control of temperature, humidity, and pressure. This makes it possible to quantify how effectively a fabric cools the body when worn, offering valuable insights into its performance.

The Cool Feeling Tester: Precision and Accuracy

When it comes to testing individual textile samples, a Cool Feeling Tester is the go-to instrument. These testers are designed to assess fabric properties such as thermal conductivity, moisture management, and evaporative cooling. By applying heat and humidity to the fabric, the Cool Feeling Tester measures how well the textile absorbs and disperses heat, creating a sensation of coolness against the skin.

A Cool Feeling Tester can provide crucial data regarding the fabric’s ability to provide comfort during wear. The tester typically measures the surface temperature of the fabric and compares it to the ambient temperature, simulating how the fabric would perform in real-life situations. This data is then used to classify fabrics according to their cooling performance, making it easier for manufacturers to select textiles that meet consumer demands for comfort.

Cool Feeling Testing Standards and Industry Impact

Standardizing Cool Feeling Testing is vital for consistency and reliability in the textile industry. Testing standards help establish benchmarks for cooling performance, ensuring that manufacturers can reliably evaluate fabric properties and compare different materials. By adhering to industry standards, textile companies can improve product quality and meet the specific needs of their target markets.

Globally recognized standards for Cool Feeling Testing have been developed by organizations such as ASTM, ISO, and AATCC. These standards outline the protocols for testing cooling fabrics and define the performance criteria that must be met to qualify as a “cooling” fabric. As such, they provide a clear and objective framework for manufacturers to follow, ensuring that their products perform as expected.

Moreover, these standards also help boost consumer confidence. With standardized testing, consumers can trust that the fabric they purchase has been rigorously evaluated for its cooling properties. As cooling fabrics continue to gain popularity, standardized testing will play an essential role in driving innovation and improving textile quality.

Conclusion

In conclusion, Cool Feeling Testing is a vital aspect of textile quality control, providing manufacturers with the tools to ensure that their fabrics deliver the desired cooling sensation. Whether using a Cool Feeling Machine or a Cool Feeling Tester, the ability to measure and evaluate a fabric’s cooling properties is essential for meeting consumer expectations and maintaining industry standards. By adhering to recognized testing protocols, textile manufacturers can ensure the production of high-quality, performance-driven products that excel in comfort and functionality. In an industry where consumer satisfaction is paramount, understanding and applying Cool Feeling Testing standards is crucial for long-term success and brand reputation.

For more information on textile testing methods/standards

or Textile Testing Machine-TESTEX textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@chiuvention.com sales@tes.hk

/home/u448362301/domains/theexpotab.com/public_html/wp-content/themes/foxiz/templates/popup.php on line 167

/home/u448362301/domains/theexpotab.com/public_html/wp-content/themes/foxiz/templates/popup.php on line 167